|

> 제품품목 > 밸브 VALVE VALVE품질과 납기를 최우선으로 하는 고객에게 신뢰받는 기업이 되겠습니다.

BELLOWS SEAL VALVE OPERATIONAL SERVICE FEATURES

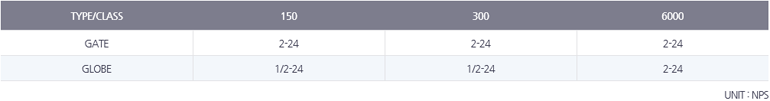

In a maintenance aspect, it is true that this type of valve is accounted less than any other type, but the valve have some important advantages as follows: VALVE SELECTION

As a general guide to valve selection suitable for a specific application, the gate valve should be used mainly for low or medium pressure steam, steam tracing lines, or other services such as heat transfer.

The globe valve should be selected for medium or high pressure steam, where the isolation of vessels may be involved in safety problem. It is also used for toxic or explosive media handling and in every case that a trouble may occur in flow regulation.

LOW FUGITIVE EMISSION VALVE Low Fugitive emission Valve (LFV) is designed and manufactured to ensure leakage of less than 100 ppm of volatile organic compounds. PK Valve has established the test facilities and made its own procedures with Emission Defence Packing (EDP) for fugitive emission test. By using the test facilities and procedures, room temperature cycle and thermal cycle testing have been performed, establishing critical design parameters necessary to achieve low fugitive emissions. LOW FUGITIVE EMISSION VALVE

- Bellows Set : 321SS(Bellows) + 316SS(Holder)

|